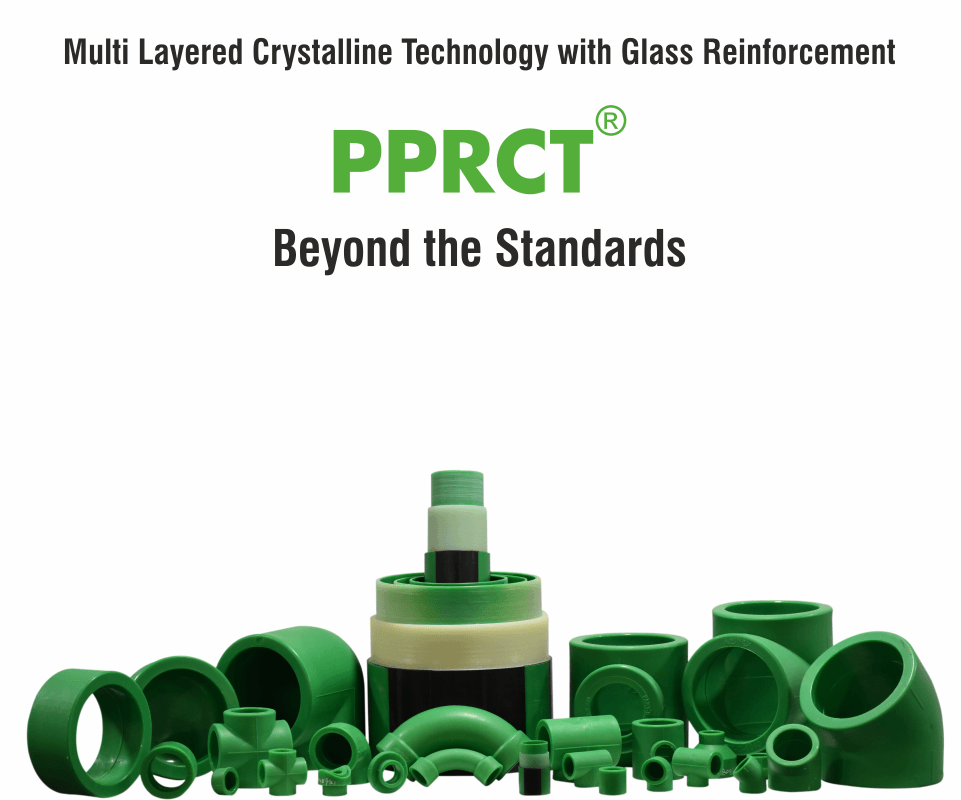

PPRCT – Beyond the Standards

Polymer pipe technology always goes through various updates due to regular research and development and due to this many manufacturers fail to cope up with this either due to lack of infrastructure or due to less technically sound or the organization fails to make up and bare the expenses for the best quality product. All these ultimately ends up in an inferior or a downgraded product.

ANJNEY TUBES INDIA is working with latest innovative technology i.e. PP grade with MRS 125 technology since 2003. ANJNEY TUBES INDIA were the first one to adopt with German DIN standards along with ISO standards with the support of BASELL.

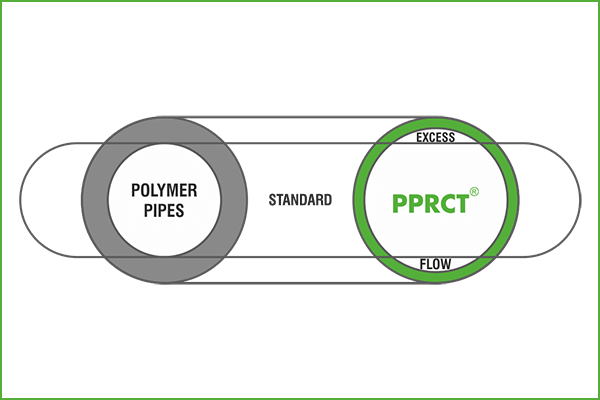

PPRCT: PPRCT is registered trademark under class 17 with the continuous effort and customer satisfaction. PPRCT is the most trusted brand providing the quality that is "BEYOND THE STANDARDS".

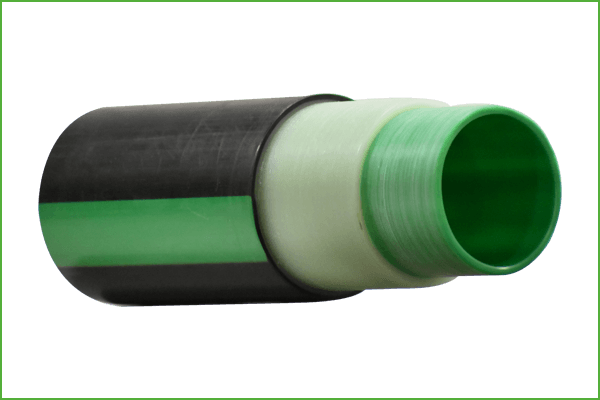

Technology: PPRCT piping adopt latest multi-layer glass reinforced technology providing the piping from latest technology raw material polymer MRS 125 having the highest mechanical properties which gives high pressure sustainability in lower wall thickness at High temperature and high pressure applications.

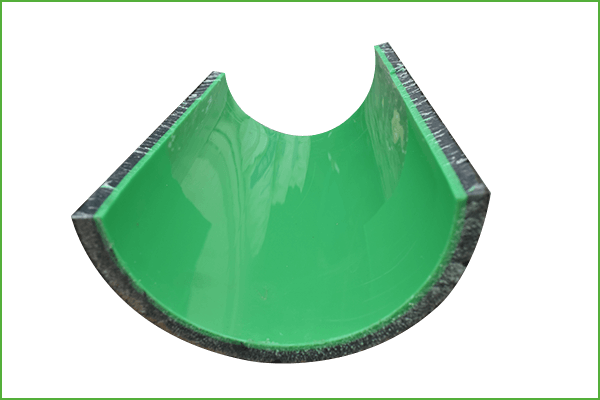

Design: Working simultaneously and fulfilling both APPLICATION as well as STANDARDS we have designed our products in a unique pattern with Green and Black layer in alternate layer technology where BLACK layer depicts the U.V resistance and GREEN layer follows the International norms for the utility application.

Standard: PPRCT Pipes are manufactured as per DIN 8077/78 & PPRCT fittings are manufactured as per ISO 16982 Part 5 to 10.

PRINCILPLE: More flow, more saving on same diameter based on the following features.

Features of PPRCT

Life of Machine and its energy consumption is highly depended on selection of the piping.

ANJNEY PPRCT PIPES are designed and maintained on the base of energy saving consideration and it’s below mentioned relevant FEATURES

Products PPCH

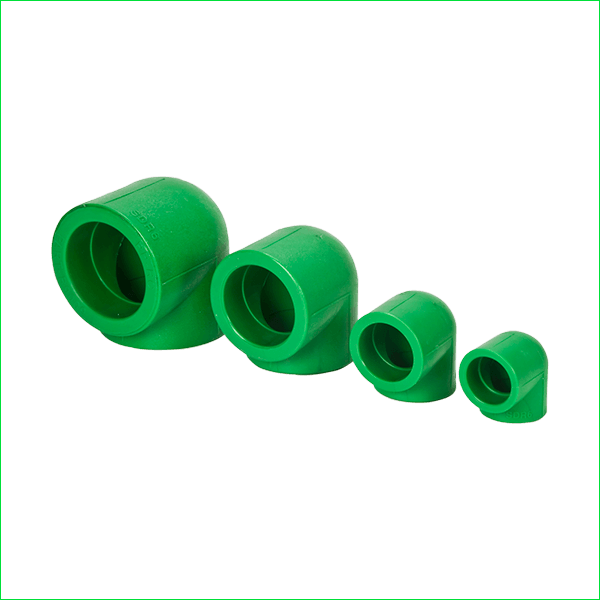

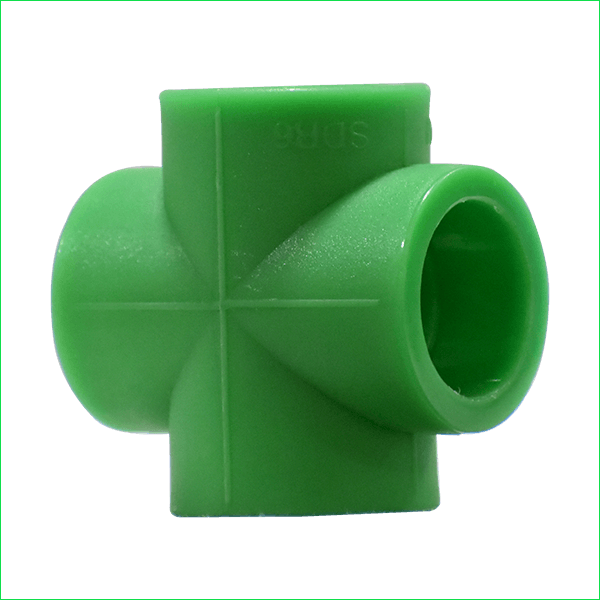

PIPE & FITTINGS

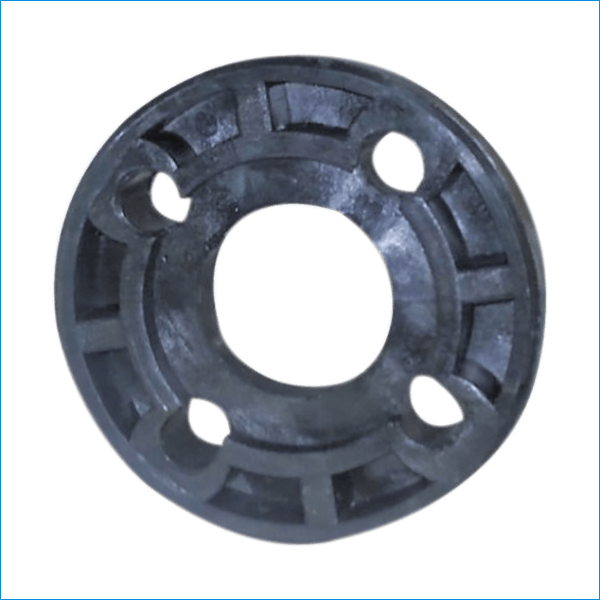

PPRCT Core Flange

When other accessories needs to be installed Core flange and Step flange are useful.

PPRCT Thermal Step Flange

When other accessories needs to be installed Step flange and Core flange are useful up to pressure of 6 bar.

PPRCT Male Threaded Joint/Adapter

When any inside threaded accessories want to be installed between the pipes.

PPRCT Female Threaded Joint/Adapter

When any outside threaded accessories want to be installed between the pipes.

PPRCT Male Threaded Elbow

When Pipe needs a turn and inside threaded accessories are to be installed.

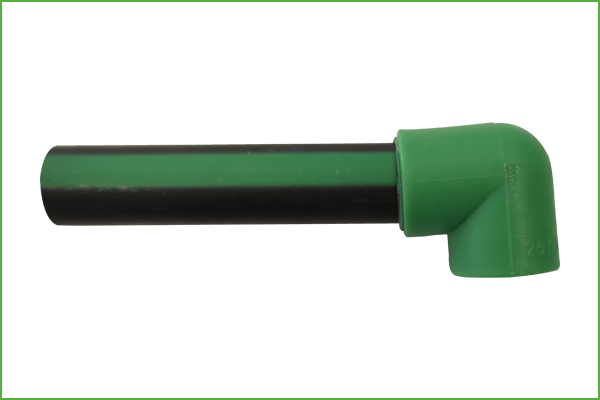

PPRCT Female Threaded Elbow

When Pipe needs a turn and outside threaded accessories are to be installed.

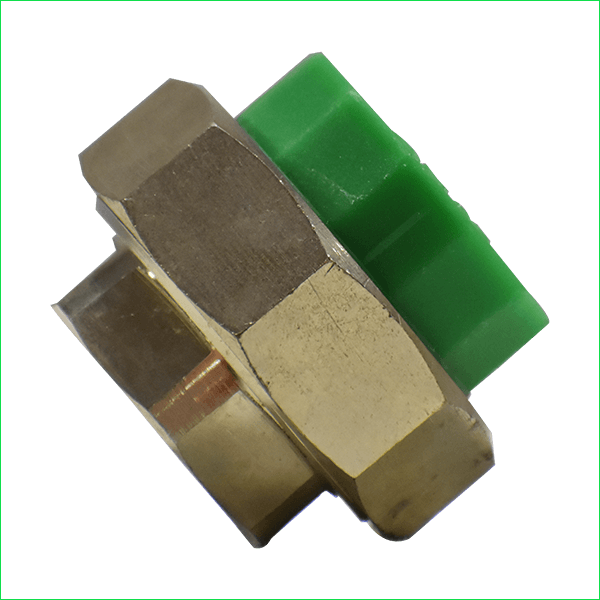

PPRCT Female Threaded Union

When outside threaded accessories are to be installed with the option of re-opening

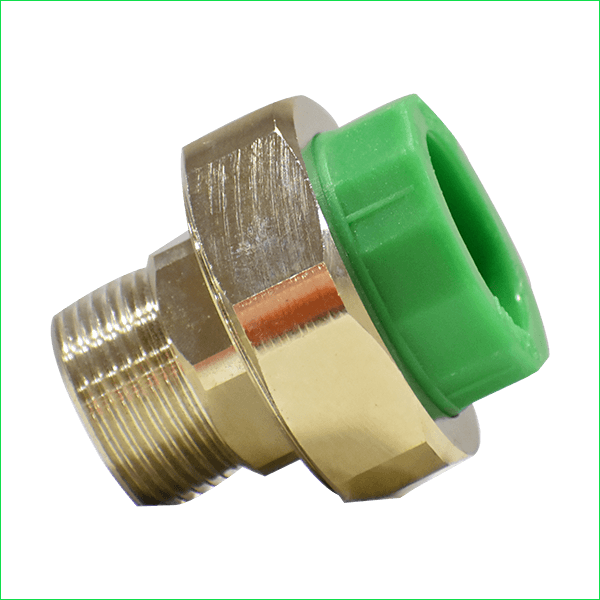

PPRCT Male Threaded Union

When inside threaded accessories are to be installed with the option of re-opening